About Beaulieu International Group

Beaulieu International Group is a global industrial group that specializes in the production of raw materials, semi-finished, and finished products for various industries. The majority of products within the BIG group are currently manufactured using non-renewable resources, primarily derived from crude oil. In response to the growing concerns related to global warming and the increasing frequency of natural disasters, the group recognized the imperative to explore alternative resources beyond finite oil reserves. Additionally, there is a concerted effort to focus on products designed to degrade naturally in the environment, thereby mitigating concerns related to litter and environmental impact.

Improving Production Efficiency with Okolys

My initial focus was on Okolys. Okolys is a biobased and biodegradable groundcover designed to naturally decompose in the environment.

Specifically formulated for weed control and fostering the growth of desired trees, Okolys serves its purpose seamlessly. As the trees reach full maturity, the need for the groundcover diminishes.

Recognizing the challenges posed by the removal of conventional groundcovers, Okolys offers an eco-friendly solution.

Being fully biodegradable, it effortlessly disintegrates over time, eliminating the inconvenience associated with the disposal of non-biodegradable alternatives.

This sustainable approach aligns with our commitment to environmentally conscious practices and underscores Okolys as a forward-thinking solution in the realm of landscaping and tree cultivation.

I applied a systematic approach to optimize the production process.

Through methodologies such as SCRA (symptom cause remedy action), Ishikawa diagrams, Pareto analysis, Design of Experiments (DOE), and milestone planning, we identified areas for improvement.

The result was a significant cost-saving of 169k per year, demonstrating the efficacy of meticulous project management.

Biomat

Buoyed by the success at Okolys, I transitioned into leading a larger project, seeking a government grant to fuel our ambitions towards more sustainable solutions.

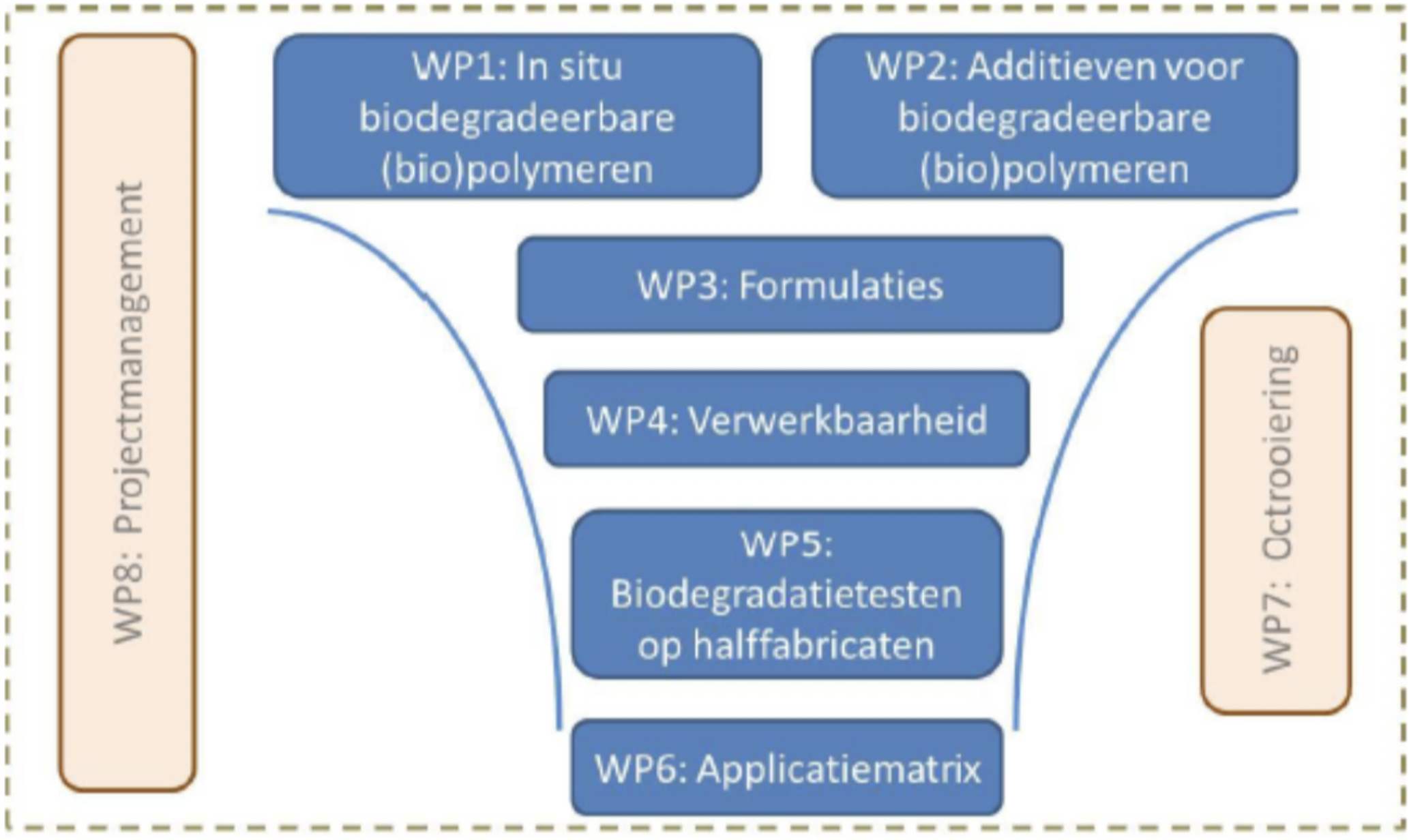

Drawing on my professional project management training, we meticulously outlined the project's innovation funnel process, emphasizing the importance of a systematic approach.

The application was successful, securing the 2 million euros needed for our endeavors. The image below illustrates the different work packages that were included in the 2 year project.

At the heart of the project was a strategic collaboration with notable partners such as Creax, KUL Propolis, UGent CPMT, VKC and OWS.

This network facilitated a comprehensive approach, allowing us to leverage diverse expertise and resources.

The synergies between academia and industry created a dynamic environment for innovation.

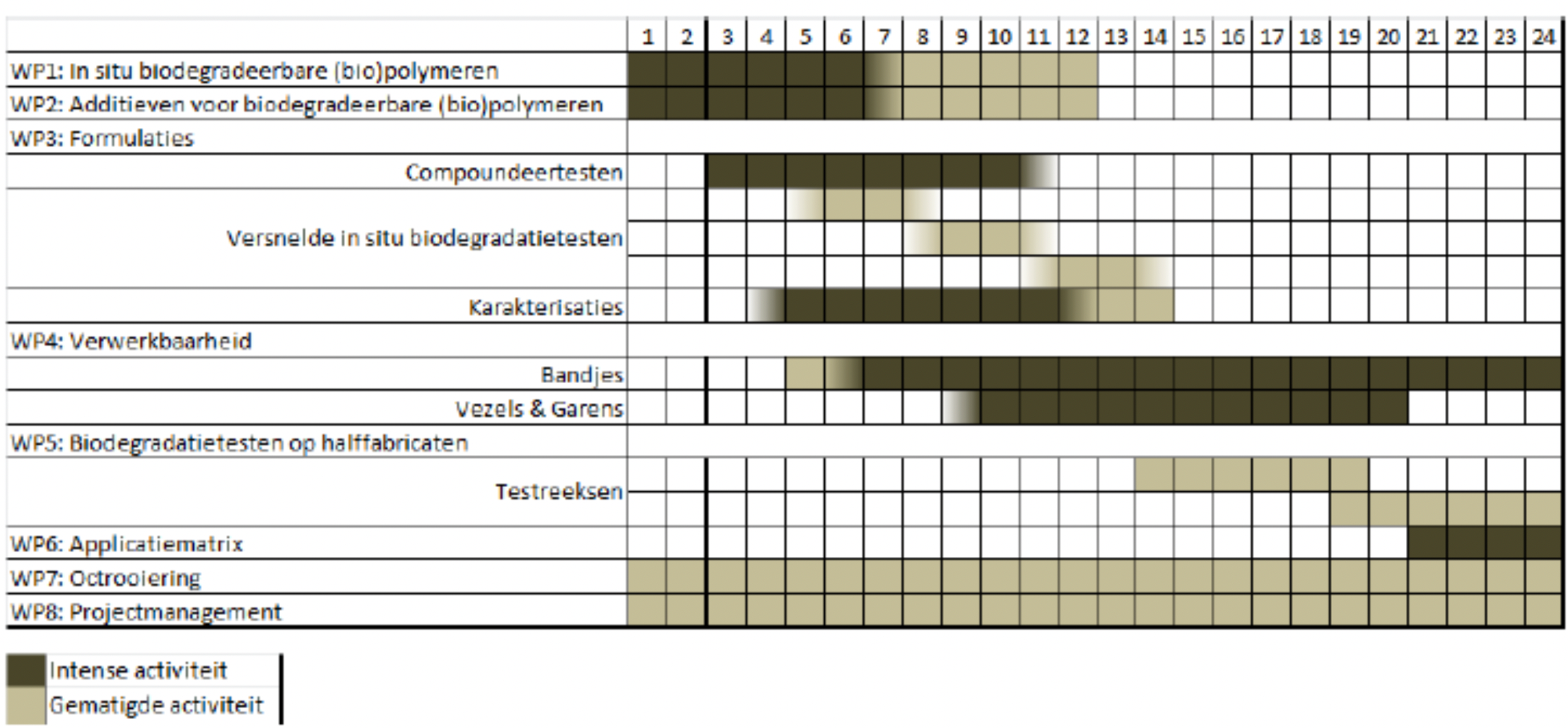

The figure below shows the planning of the different work packages over the 2 year length of the project.

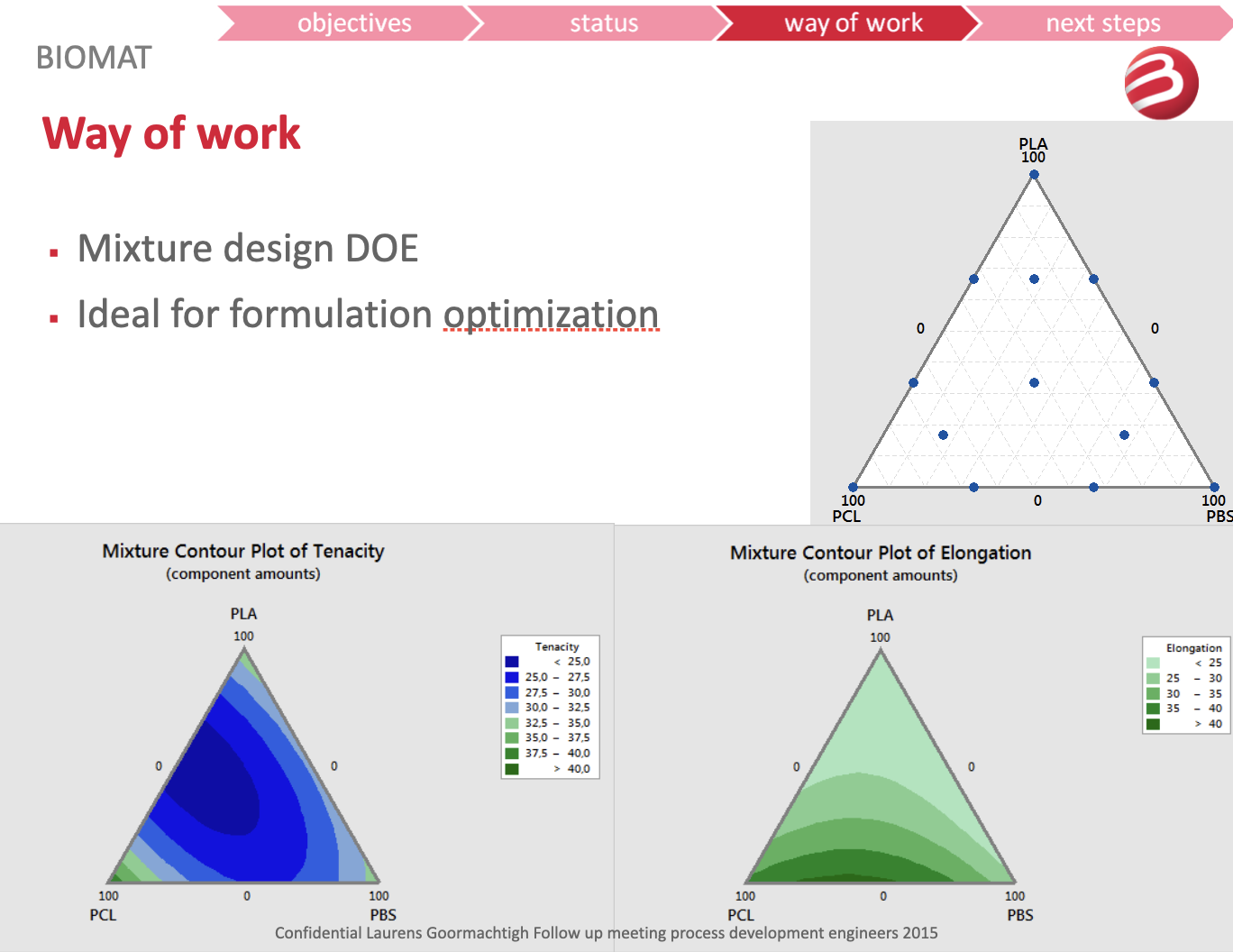

In the BIOMAT project, I employed a systematic and data-driven approach to optimize the formulation of our product, leveraging the power of Design of Experiment (DOE) methodology with the aid of the statistical tool Minitab.

This innovative approach allowed us to intricately analyze and understand the multifaceted relationship between various input factors and the desired output parameters.

The use of Minitab enabled us to create a detailed graph illustrating the diverse formulations and their respective effects on critical product attributes, such as processability, biodegradability, biobased content, and application characteristics.

This visual representation not only provided valuable insights into the complex interplay of these factors but also served as a guiding map for identifying the optimal formulation that aligned seamlessly with our project objectives.

The successful application of DOE methodology and Minitab in the BIOMAT project underscored the importance of precision and statistical rigor in achieving targeted outcomes in product development and optimization.

The figure below displays contour plots representing the mixed design Design of Experiment (DOE) setup.

Positioned in the top right corner are various formulations, combinations of PCL, PBS, and PLA.

The contour plots vividly depict the impact of these formulations on both elongation and tenacity, providing a visual representation of the intricate relationship between the variables.

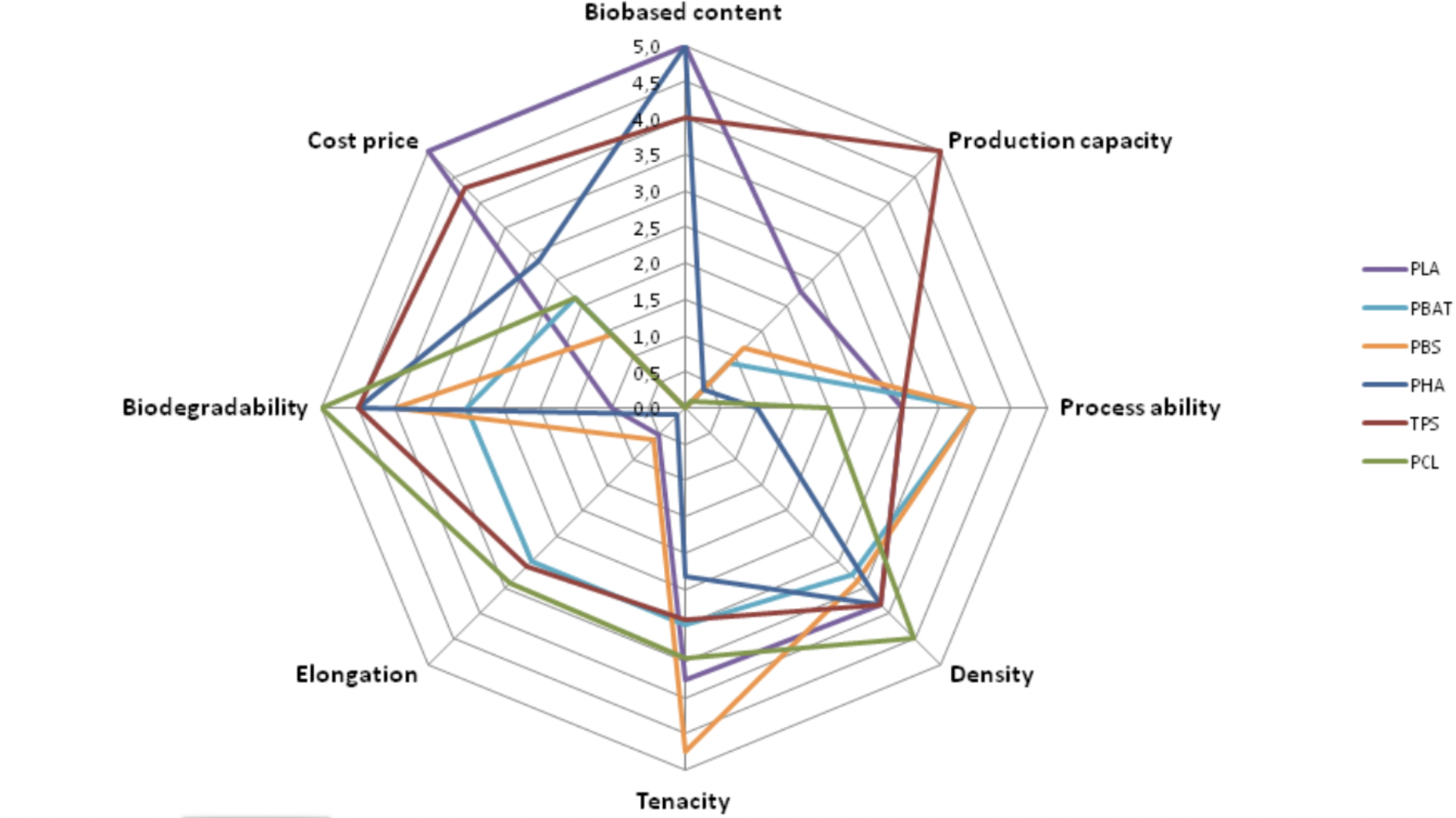

The visual representation below encapsulates the wealth of knowledge garnered throughout the BIOMAT project.

Rigorous testing across various polymers and their blends yielded profound insights into their processability, degradability, mechanical properties, and financial implications.

The comprehensive profiles depicted in the graph provide a nuanced understanding of each material.

This graphical representation proved instrumental in formulating innovative compositions for our new line of biobased and biodegradable products.

Outcomes and achievements

The outcomes of our efforts were substantial and far-reaching:

- We realised a 169k euro per annum savings after optimising the Okolys production process.

- We applied for and obtained a 2 million euro government grant.

- We secured a patent for biodegradable ground covers, a significant milestone in our commitment to sustainability.

- The investment in a pilot-scale extrusion line marked a strategic move, solidifying our legacy within the R&D department.

- Beyond tangible achievements, we established a robust knowledge base encompassing innovative biopolymers and their blends. This included an in-depth understanding of their properties, processability, degradability, and a comprehensive application matrix.

Conclusion

My tenure in this role not only showcased my proficiency in project management but also highlighted the transformative impact that well-executed R&D initiatives can have. From optimizing production processes to securing government grants and pioneering sustainable solutions, this case study is a testament to my ability to drive innovation, collaborate effectively, and deliver tangible results.

Links